New material High-end commercial PVC floor leather brand

Product Parameters

| Brand: Quanshun | Series: Youjinglong Series |

| Material: Environmentally friendly PVC | Shape: Roll |

| Floor type: Multi-layer composite | Surface design: "Lotus Leaf Shield" ultra-fouling UV layer |

| Thickness: 2mm | Transparent wear-resistant layer thickness: 0.4mm (40 silk) / 0.5mm (50 silk) |

| Standard roll size: 2 meters wide * 20 meters long |

| Technical data | Test method | Test results |

| Total thickness | EN 428 | 2.0mm |

| Wear layer thickness | EN 429 | 0.35mm /0.4mm |

| Total weight | EN 430 | 1800g/㎡/3100g/㎡ |

| Roll width | EN 426 | 2m |

| Roll length | EN 426 | 20m |

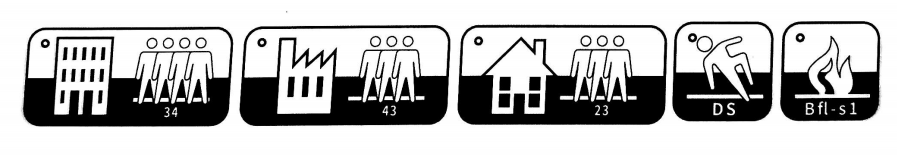

| Fire resistance | GB8624-2006 | Bf1 |

| Static indentation | EN 433 | 0.16 |

| Light fastness | EN ISO 1005-302 | ≥6 |

| Chemical resistance | EN 423 | Good |

| Dimensional stability | EN 434 | 0.05%-0.10% |

| Slip resistance | DIN 51130 | R9 |

| Castor chair | EN 425 | 80000 or above |

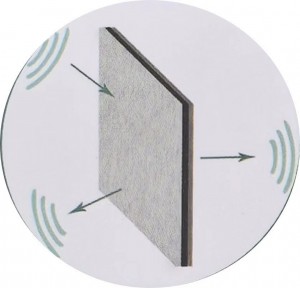

| Sound insutation | EN ISO 717-2 | 19dB |

| Electrical resistance | EN 1081 | ≤10² |

| Anti iodine | ASTM F925 | Excellent |

| Limit ofharmful substences | GB 18586-2001 | Qualified |

Additional Property

| Castor chair | Antistatic Behavious |

| Underfoor Heating | Chemical Resistance |

DOP test value

Not detected

Children's toy standard

Heavy metals not detected

Formaldehyde emission

Test value 0

REACH

EU high-risk carcinogens

Not detected

TVOC

Emission 28-day test

European standard 1/200

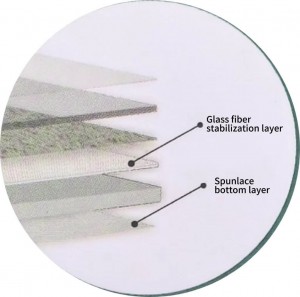

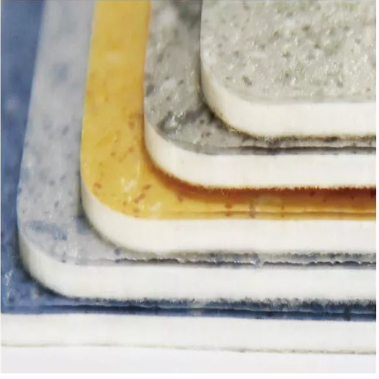

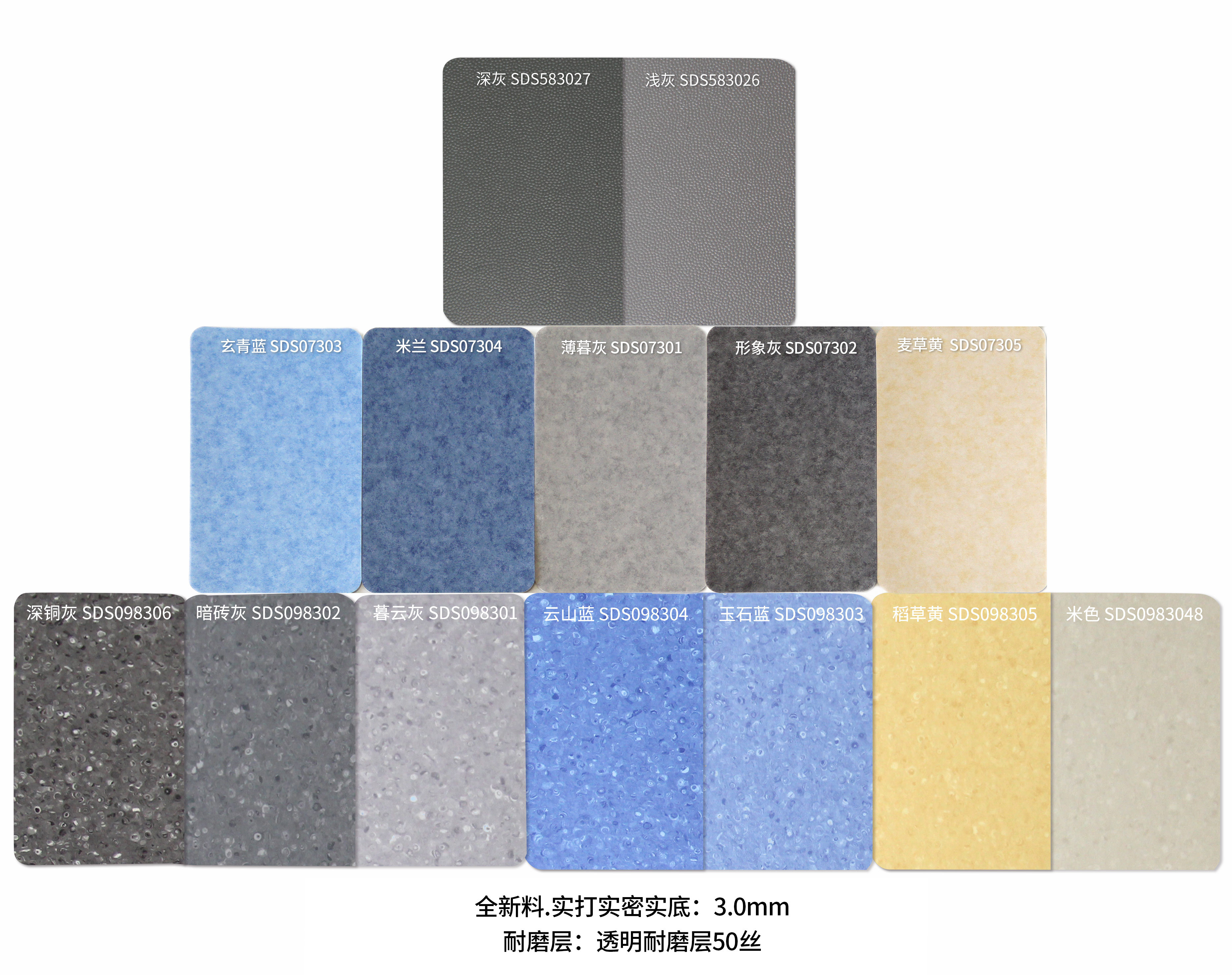

Solid color base-double stable layer series

Fiberglass + spunlace fabric is more stable, stronger and easier to lay

Product Introduction

More stable

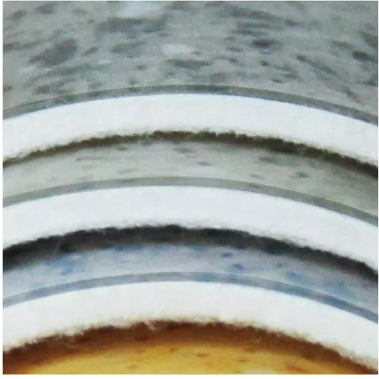

The structure of glass fiber + spunlace fabric: double stable layers,

Each can be used as a stable layer independently,

Each can reach the national standard as a stable layer independently,

The two together make the product more stable, far exceeding the national standard.

Stronger

Structure of glass fiber + spunlace fabric:

Product strength is greatly improved:

Cannot be pulled, torn or folded.

Easier to lay

The bottom layer is made of spunlace material, which is more tolerant of the drying time of the floor leather; when constructing the back cover, the drying time is very strict. If the time is too long, the viscosity of the glue will be reduced; if the time is too short, it will not be firmly attached; skilled workers are required to flexibly control the temperature and humidity, turning the floor laying into a craftsman's work, and problems often occur in this link.

Easier to lay flat

Glass fiber + spunlace fabric structure: double stable layer,

making the product more stable, not easily deformed by external temperature

and extrusion, etc., with good flatness, easier to lay flat,

reducing the difficulty of construction.

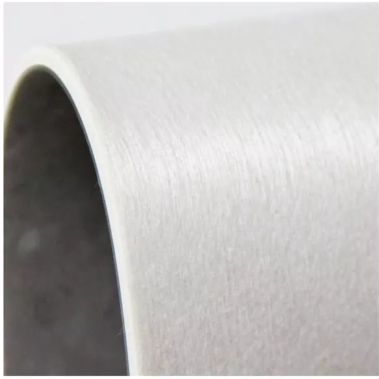

Easier to replace

The bottom layer is made of spunlace cloth material. When replacing,

the base layer can be left intact and the entire floor glue can be completely peeled off,

reducing the cost of replacement and making the removal of the floor glue simple, convenient and low-cost.

Low requirements for the base floor

The base layer uses spunlace material, which reduces the requirements for the base floor and provides stronger bonding strength. This design reduces the cost of base floor treatment, facilitates the installation process, and enhances the stable connection between the floor and the ground.

Sound absorption

The bottom layer is made of spunlace material, which has better sound absorption effect. The unique fiber structure and high porosity of spunlace make sound waves easier to absorb and disperse, reducing reflection and transmission. At the same time, the spunlace fits tightly with the floor, reducing the transmission of sound through the gaps, further improving the sound absorption performance.

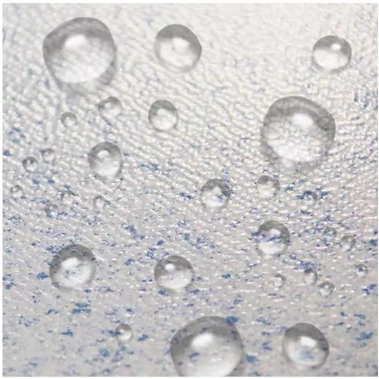

Moisture-proof

The bottom layer is made of spunlace material, which has better moisture-proof effect.

Spunlace can effectively prevent moisture penetration, tightly bond with the floor, and reduce moisture intrusion.

At the same time, spunlace also has good air permeability, helping the floor stay dry. These characteristics together improve the moisture-proof performance of the floor.

Advantages of polymer industrial coil floor:

1. Super strong compression resistance, can carry 30 tons of trucks and forklifts

2. Super wear resistance, 0.8mm polymer wear-resistant layer

3. Excellent antibacterial performance, Escherichia coli ATCC8739, Staphylococcus aureus ATCC6538P antibacterial rate 99.9%

4. Excellent antistatic performance

5. Excellent resistance to strong acid and alkali, 60% sulfuric acid solution, 55% sodium hydroxide solution, level 0

6. Fire retardant polymer industrial coil floor, fire rating BF1 level* and above, SGS third-party test report can be provided

Applicable to: electronics, microelectronics industry, pharmaceutical industry that requires high cleanliness, beauty, dust-free and sterility, and GMP standard, and can also be used in various industrial plants such as electronics and electrical schools, offices, food factories, chemical plants, etc.

01

Production of new materials

The product is made of new materials without recycled materials, which is more environmentally friendly and has stronger performance. This ensures the quality and reliability of the floor and provides users with a long-lasting and durable use experience.

02

"Lotus Leaf Shield" ultra-fouling-resistant UV layer

The surface layer adopts "Lotus Leaf Shield" UV technology, which has super strong stain resistance. This special coating can effectively prevent the adhesion of stains, keep the floor surface clean, and reduce the burden of cleaning work.

03

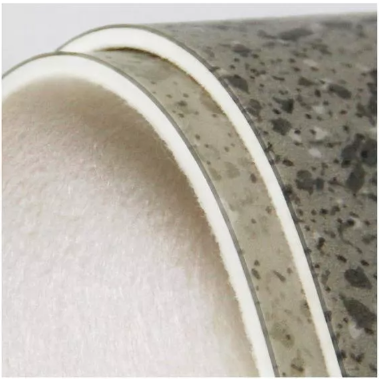

Embossed with rock pattern design

Embossed with rock pattern design can not only give the floor anti-slip function, but also have a beautiful appearance. More importantly, at the corners of the pattern, a gentle slope design is adopted to ensure that dirt will not hide. This design not only provides excellent anti-slip performance, but also makes it easy to clean and keep the floor clean and stain-free.

04

Double-layer stabilization layer

The double-layer structure of glass fiber and spunlace cloth makes the shrinkage rate of the product close to 0. This means that the floor can maintain a stable size under different temperature and humidity conditions, avoiding problems such as deformation or cracking.

05

0 Porous dense and pressure-resistant layer

The dense layer is manufactured using a single-layer extrusion process and is vacuum-extracted during the production process to eliminate the air in the middle, making the dense layer of the floor free of pores. This treatment makes the product more dense and strong, prolongs the service life of the floor, and can withstand high-intensity commercial use requirements.

06

Spunlace fabric sound-absorbing backing layer

The bottom layer is made of spunlace fabric material, which has the advantage of reducing the requirements for the base floor and providing stronger bonding strength. This design not only facilitates the installation process, but also enhances the stable connection between the floor and the ground.

07

Stain-resistant, durable, stable, and environmentally friendly

These advantages make 2.0mm thick dense commercial flooring an ideal choice for commercial places. It has excellent stain resistance, durability and stability, while meeting environmental protection requirements and providing users with high-quality flooring solutions.

08

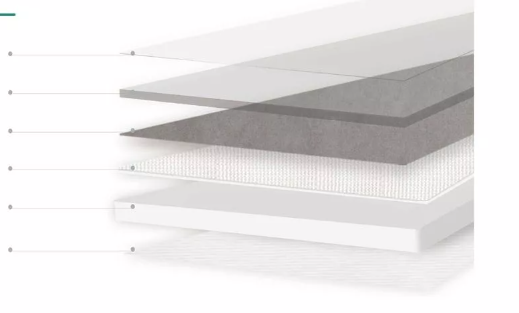

Quan Shun-Youjinglong Series Flooring-Structure Diagram

| Ultra-fouling-resistant UV layer |

| thickened transparent wear-resistant layer |

| Printing layer |

| Glass fiber stabilization layer |

| 0-pore dense pressure-resistant layer |

| Spunlace sound-absorbing backing layer |

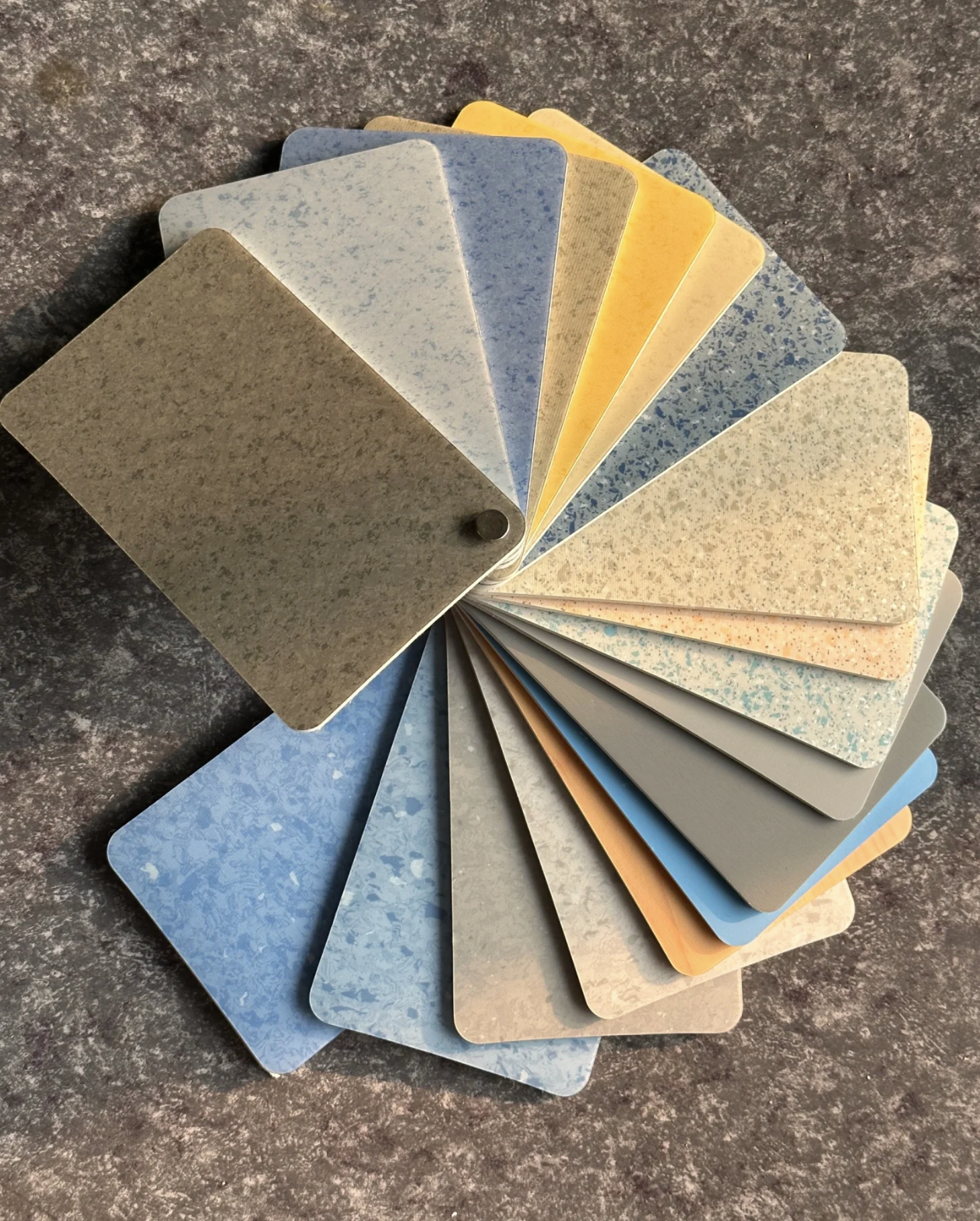

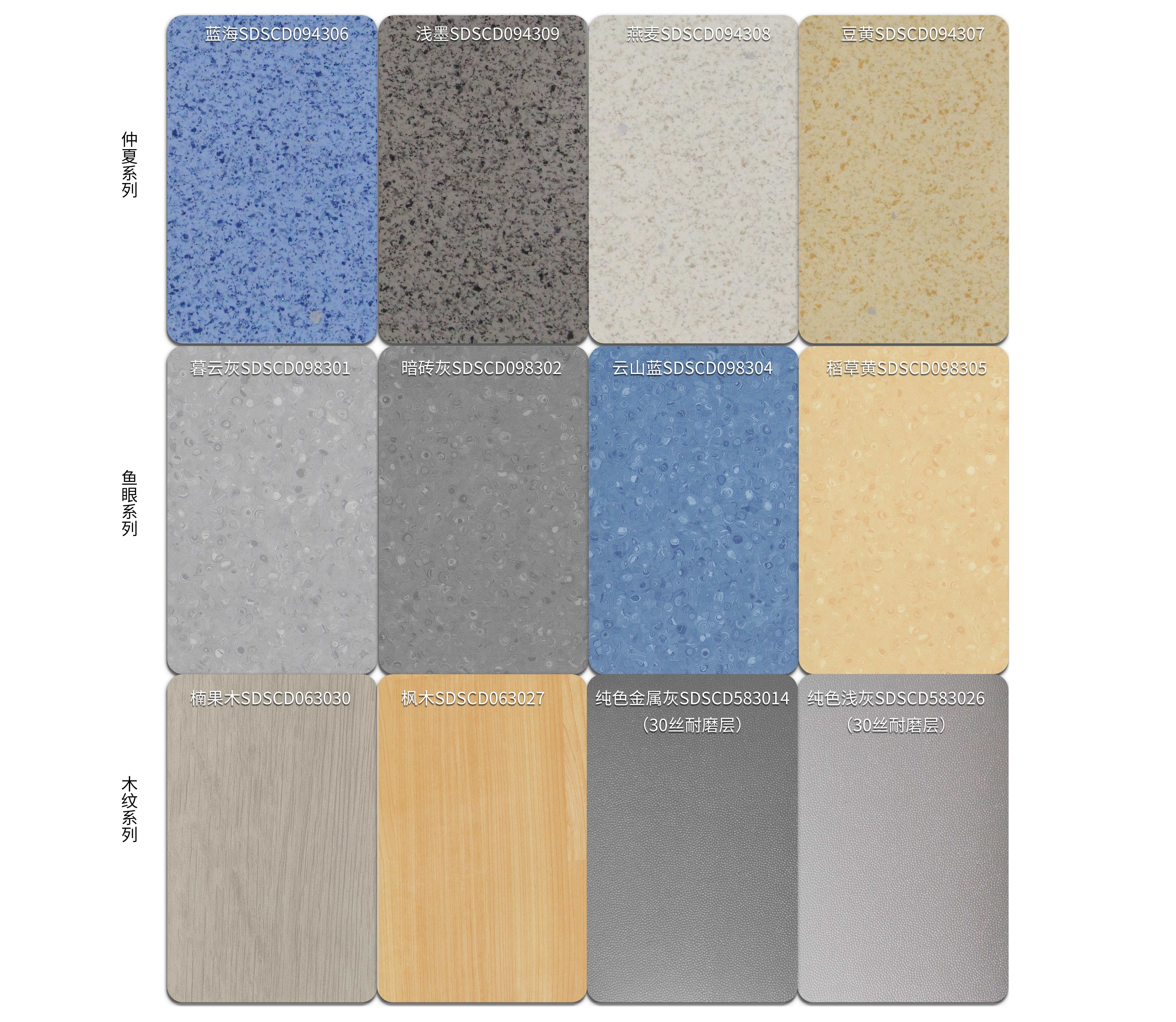

Product color card

Product real scene application diagram

Restaurant

Nursery school

Gymnasium

Hospital

Nursing home

Factory production workshop

Office Building

Shopping malls and entertainment venues

Bedroom