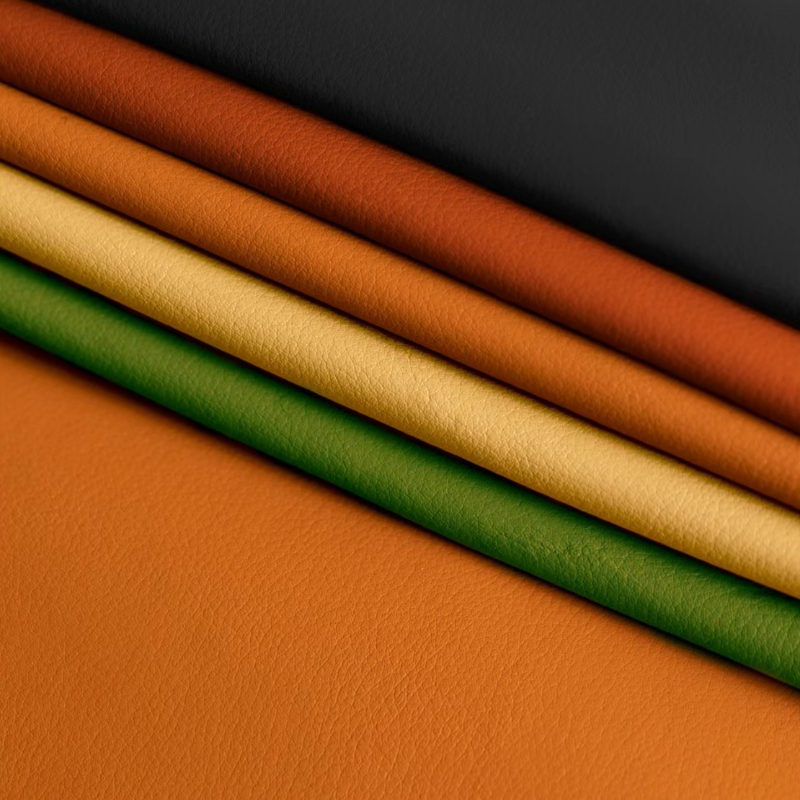

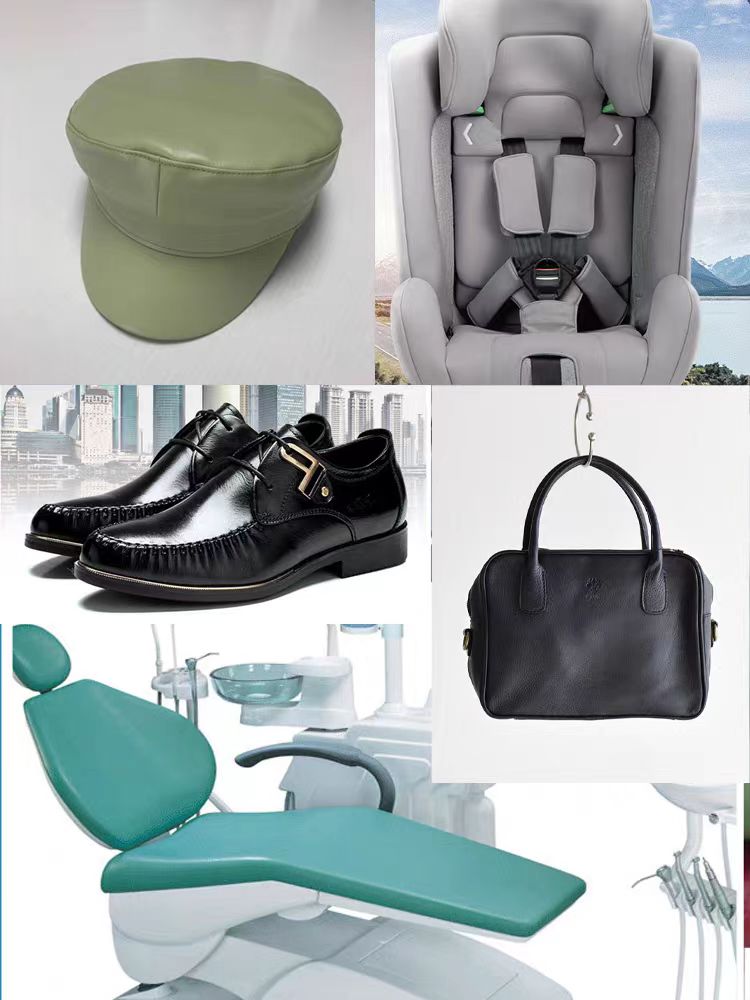

Consumers around the world prefer leather products, especially leather car interiors, leather furniture, and leather clothing. As a high-end and beautiful material, leather is widely used and has a lasting charm. However, due to the limited number of animal furs that can be processed and the need for animal protection, its output is far from meeting the various needs of humans. Against this background, synthetic leather came into being. Synthetic leather can be divided into many types due to different materials, different types of substrates, different production processes, and different uses. Here is an inventory of several common leathers on the market.

Genuine leather

Genuine leather is made by coating the surface of animal skin with a layer of polyurethane (PU) or acrylic resin. Conceptually, it is relative to artificial leather made of chemical fiber materials. The genuine leather mentioned in the market is generally one of the three types of leather: top layer leather, second layer leather, and synthetic leather, mainly cowhide. The main characteristics are breathability, comfortable feel, strong toughness; strong odor, easy discoloration, difficult care, and easy hydrolysis.

PVC leather

PVC leather, also known as polyvinyl chloride artificial leather, is made by coating fabric with PVC, plasticizers, stabilizers and other additives, or by coating a layer of PVC film, and then processed through a certain process. The main features are easy processing, wear resistance, aging resistance, and cheapness; poor air permeability, hardening and brittle at low temperatures, and stickiness at high temperatures. The large-scale use of plasticizers harms the human body and causes serious pollution and odor, so it is gradually abandoned by people.

PU leather

PU leather, also known as polyurethane synthetic leather, is made by coating fabric with PU resin. The main features are comfortable feel, close to genuine leather, high mechanical strength, many colors, and a wide range of applications; not wear-resistant, almost airtight, easy to be hydrolyzed, easy to delaminate and blister, easy to crack at high and low temperatures, and the production process pollutes the environment, etc.

Microfiber leather

The base material of microfiber leather is microfiber, and the surface coating is mainly composed of polyurethane (PU) or acrylic resin. Its characteristics are good hand feel, good shaping, strong toughness, good wear resistance, good uniformity, and good folding resistance; it is easy to break, not environmentally friendly, not breathable, and has poor comfort.

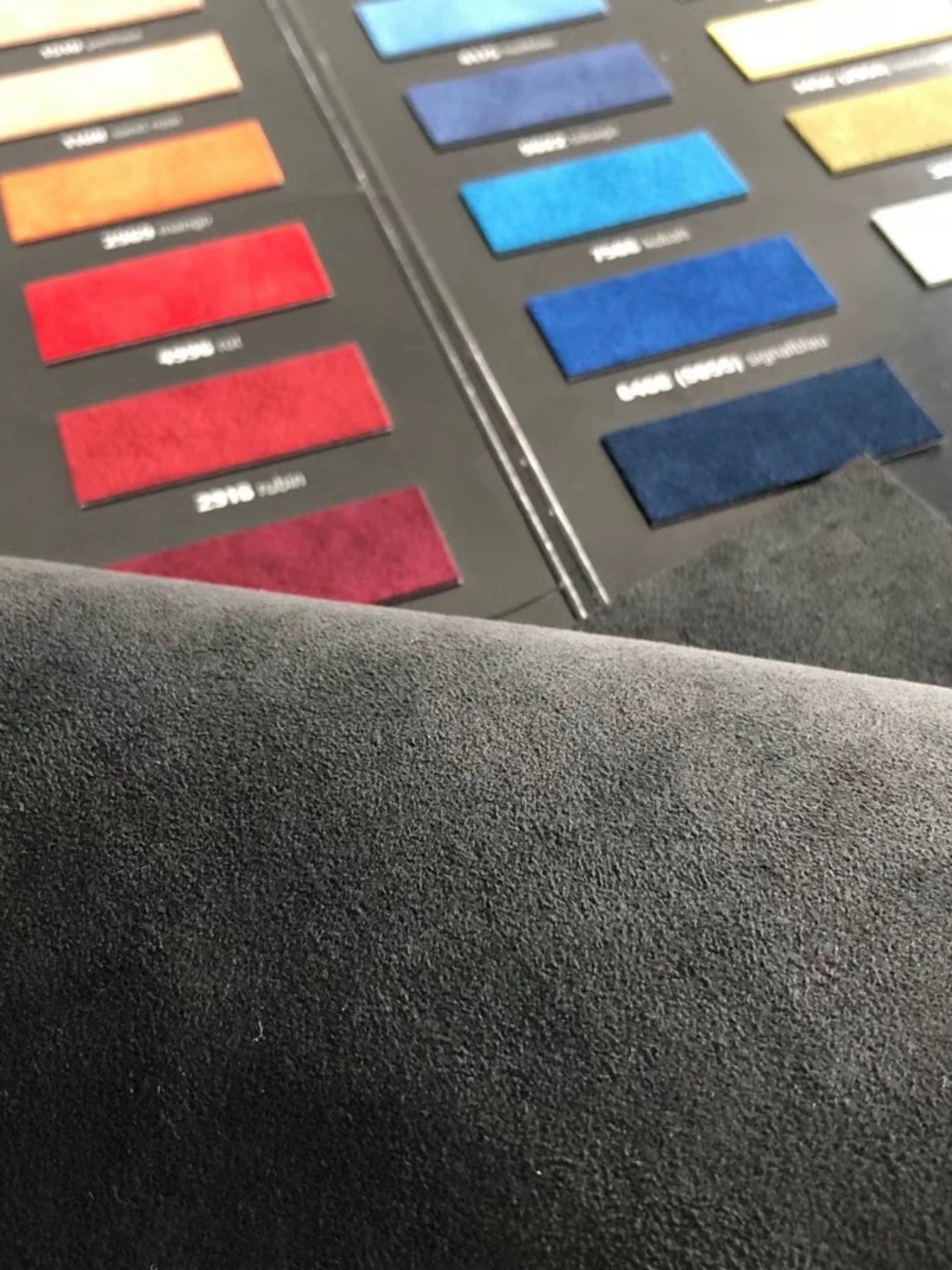

Technology cloth

The main component of technology cloth is Polyester. It looks like leather, but feels like cloth. Its characteristics are the texture and color of genuine leather, good breathability, high comfort, strong durability, and free matching of fabrics; but the price is high, the maintenance points are limited, the surface is easy to get dirty, not easy to take care of, and it will change color after cleaning.

Silicone leather (semi-silicon)

Most of the semi-silicon products on the market are coated with a thin layer of silicone on the surface of solvent-free PU leather. Strictly speaking, it is PU leather, but after the silicone layer is applied, the leather's easy cleanability and waterproofness are greatly enhanced, and the rest are still PU characteristics.

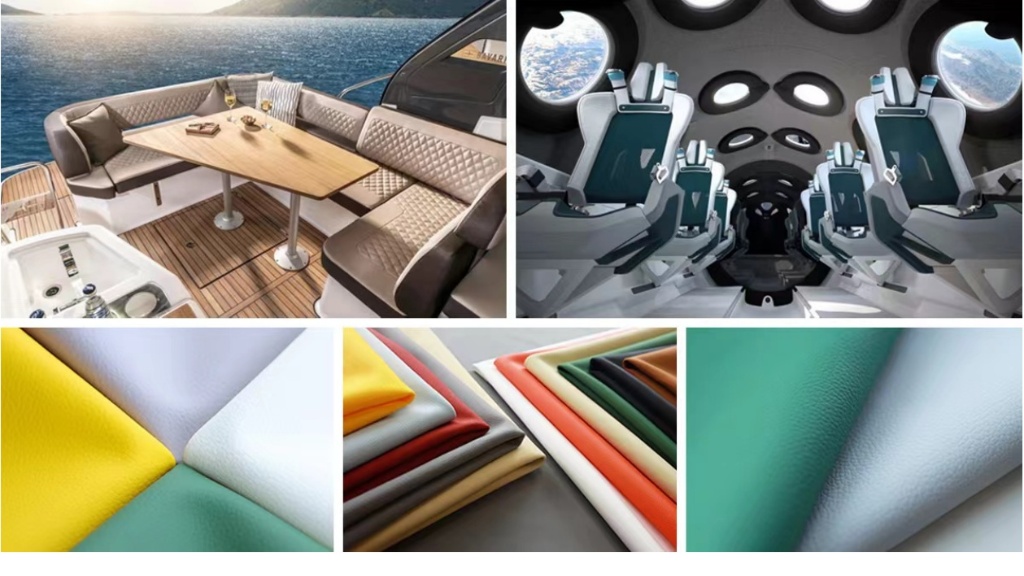

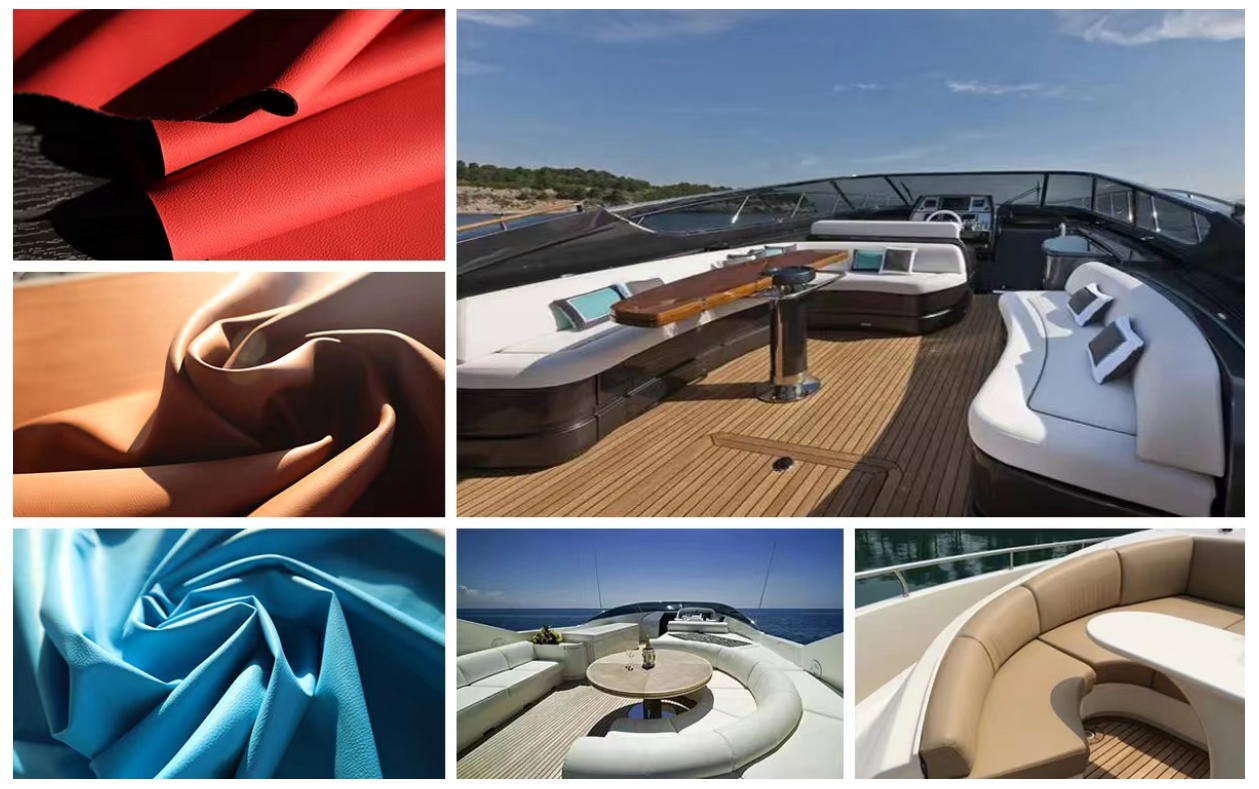

Silicone leather (full silicone)

Silicone leather is a synthetic leather product that looks and feels like leather and can be used instead of it. It is usually made of fabric as the base and coated with 100% silicone polymer. There are mainly two types of silicone synthetic leather and silicone rubber synthetic leather. Silicone leather has the advantages of no odor, hydrolysis resistance, weather resistance, environmental protection, easy cleaning, high and low temperature resistance, acid, alkali and salt resistance, light resistance, heat aging resistance, yellowing resistance, bending resistance, disinfection, strong color fastness, etc. It can be used in outdoor furniture, yachts and ships, soft package decoration, car interior, public facilities, sports goods, medical equipment and other fields.

Such as the popular environmentally friendly organic silicone leather, which is made of environmentally friendly liquid silicone rubber. Our company independently developed a two-coating short-process automatic production line and adopted an automated feeding system, which is efficient and automatic. It can produce silicone rubber synthetic leather products of various styles and uses. The production process does not use organic solvents, there is no wastewater and waste gas emission, and green and intelligent manufacturing is realized. The Scientific and Technological Achievement Appraisal Committee organized by the China Light Industry Federation believes that the "High-performance Special Silicone Rubber Synthetic Leather Green Manufacturing Technology" developed by Dongguan Quanshun Leather Co., Ltd. has reached the international leading level.

Silicone leather can also be used normally under many harsh conditions. For example, in the hot sun outdoors, silicone leather can withstand the wind and sun for a long time without aging; in the cold weather in the north, silicone leather can remain soft and skin-friendly; in the humid "return of the south" in the south, silicone leather can be waterproof and breathable to avoid bacteria and mold; in hospital beds, silicone leather can resist blood stains and oil stains. At the same time, due to the excellent stability of silicone rubber itself, its leather has a very long service life, no maintenance, and will not fade.

Leather has many names, but basically the above materials. With the current increasingly stringent environmental pressure and the government's environmental monitoring efforts, leather innovation is also imperative. As a pioneer in the leather fabric industry, Quanshun Leather has been focusing on the research and production of environmentally friendly, healthy and natural silicone polymer fabrics for many years; the safety and durability of its products far exceed other similar products on the market, whether in terms of internal microstructure, appearance texture, physical properties, comfort, etc., they can be comparable to high-grade natural leather; and in terms of quality, functionality, etc., it has surpassed real leather and replaced its important market position.

I believe that in the future, Quanshun Leather will be able to provide consumers with more environmentally friendly, high-quality natural leather fabrics. Let's wait and see!

Post time: Sep-12-2024