Company Profile

Quan Shun Leather was established in 2017.

It is a pioneer in new environmentally friendly leather materials. It is committed to upgrading existing leather products and leading the green development of the leather industry.

The company's main product is PU synthetic leather.

Furniture and home furnishings

Leather is widely used in beds, sofas, bedside tables, chairs, outdoor furniture and other areas.

Leather Is Everywhere

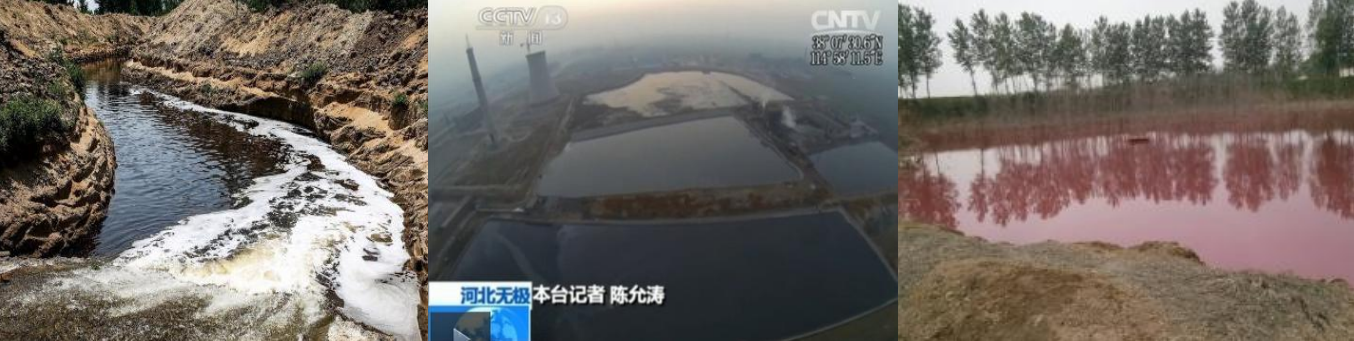

The Traditional Leather Industry Has A Lot Of Problems

High pollution, high harm

1. The production process leads to serious water pollution

2. Most of the workers in leather factories have rheumatism or asthma

Toxic and harmful

The products produced continue to release a large amount of toxic and harmful substances in use after several years, which is harmful to health. Especially in closed spaces such as indoor furniture and cars

Coating technology is monopolized by foreign countries

Related product technologies are in the hands of foreign multinational companies, and slightly

high-end products often threaten China with out-of-stock

Water Pollution During Production

Tannery wastewater has a large discharge volume, high pH value, high chroma, a wide variety of pollutants, and complex composition, making it difficult to treat. The main pollutants include heavy metal chromium, soluble protein, dander, suspended matter, tannin, lignin, inorganic salts, oils, surfactants, dyes, and resins. A large part of these wastewaters are directly discharged without any treatment.

High Energy Consumption: Large Water And Electricity Users

300,000 households use water

Water consumption is 3 cubic meters/month

Electricity consumption is 300 kWh/month

Water consumption: about 300,000 households

Electricity consumption: about 30,000 households

Medium-scale leather factories use water

Water consumption: about 28,000-32,000 cubic meters

Electricity consumption: about 5,000-10,000 kWh

A medium-sized leather factory with a daily output of 4,000 cowhides consumes about 2-3 tons of standard coal, 5,000-10,000 kWh of electricity, and 28,000-32,000 cubic meters of water. It consumes 750 tons of coal, 2.25 million kWh of electricity, and 9 million cubic meters of water each year. It can pollute a West Lake in a year and a half.

Harm To The Health of Production Workers

Rheumatism - Leather factory water plants use a large amount of chemicals to soak leather to achieve the required feel and style. People who have been engaged in this kind of work for a long time generally suffer from varying degrees of rheumatism.

Asthma - The main equipment in the finishing process of the leather factory is the spraying machine, which sprays fine chemical resin on the surface of the leather. People engaged in this kind of work all suffer from severe allergic asthma.

Traditional Leather Continues To Volatilize Harmful Substances Throughout Life

Danger chemical pollutants: "TVOC" represents hundreds of chemicals in indoor air

aromatic hydrocarbons, formaldehyde, benzene, alkanes, halogenated hydrocarbons, mold, xylene, ammonia, etc.

These chemicals can cause infertility, cancer, intellectual disability, asthma cough, dizziness and weakness, fungal skin infections, allergies, leukemia, immune system disorders and other diseases

In recent years, with the rise of the industrial revolution, the consumption level has continued to rise, and the demand in the current leather industry consumer market has also continued to increase. However, the leather industry has been slowly updating and replacing over the past 40 years, mainly focusing on animal skins, PVC and solvent-based PU, and low-priced homogeneous products are flooding the market. With the increasing environmental awareness of the new generation of consumers, the traditional leather industry has been gradually abandoned by people due to its high pollution and unsafe problems. Therefore, finding a truly environmentally friendly and safe sustainable leather fabric has become an industry problem that needs to be overcome.

The progress of the times has promoted market changes, and in this wave of change, silicone leather came into being and became a new favorite in the development trend of new material leather and environmentally friendly and healthy leather in the 21st century. At this time, as a high-tech innovative enterprise, the silicone leather produced by Quanshun Leather has become the first choice for people's environmentally friendly and healthy products because of its low-carbon safety, green environmental protection, and natural comfort.

Quanshun Leather Co., Ltd. has been focusing on the research and production of environmentally friendly, healthy and natural silicone polymer fabrics for many years. Through continuous innovation and development, the company now has a professional production workshop, advanced first-level production equipment, etc.; its team specially designs and develops according to the production requirements of silicone leather. No water is used in the production process, and organic solvents and chemical additives are refused. The whole process is low-carbon and environmentally friendly, without the release of harmful substances or water pollution. It not only solves the environmental pollution problems caused by the traditional leather industry, but also ensures that the product has lower VOCs release and safer performance.

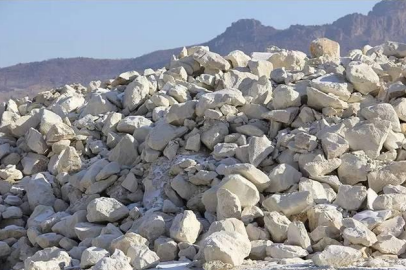

Silicone leather is a new type of environmentally friendly synthetic leather. Compared with traditional leather, it is more in line with the requirements of low carbon, environmental protection and green. It has laid a more environmentally friendly tone in the selection of raw materials. It uses common silica minerals (stones, sand) in nature as the basic raw materials, and uses high-temperature polymerization to become organic silicone that is widely used in baby bottles and nipples, and finally coated on specially customized environmentally friendly fibers. It also has advantages in skin-friendly, comfortable, anti-fouling and easy-to-clean properties. Silicone leather has extremely low surface energy and hardly reacts with other materials, so it has extremely high anti-fouling properties. Stubborn stains such as blood, iodine, coffee, and cream in daily life can be easily removed with mild water or soapy water, and will not affect the performance of silicone leather, greatly saving the cleaning time of internal and external decorative materials, and reducing the difficulty of cleaning, which is in line with the modern people's simple and efficient life concept.

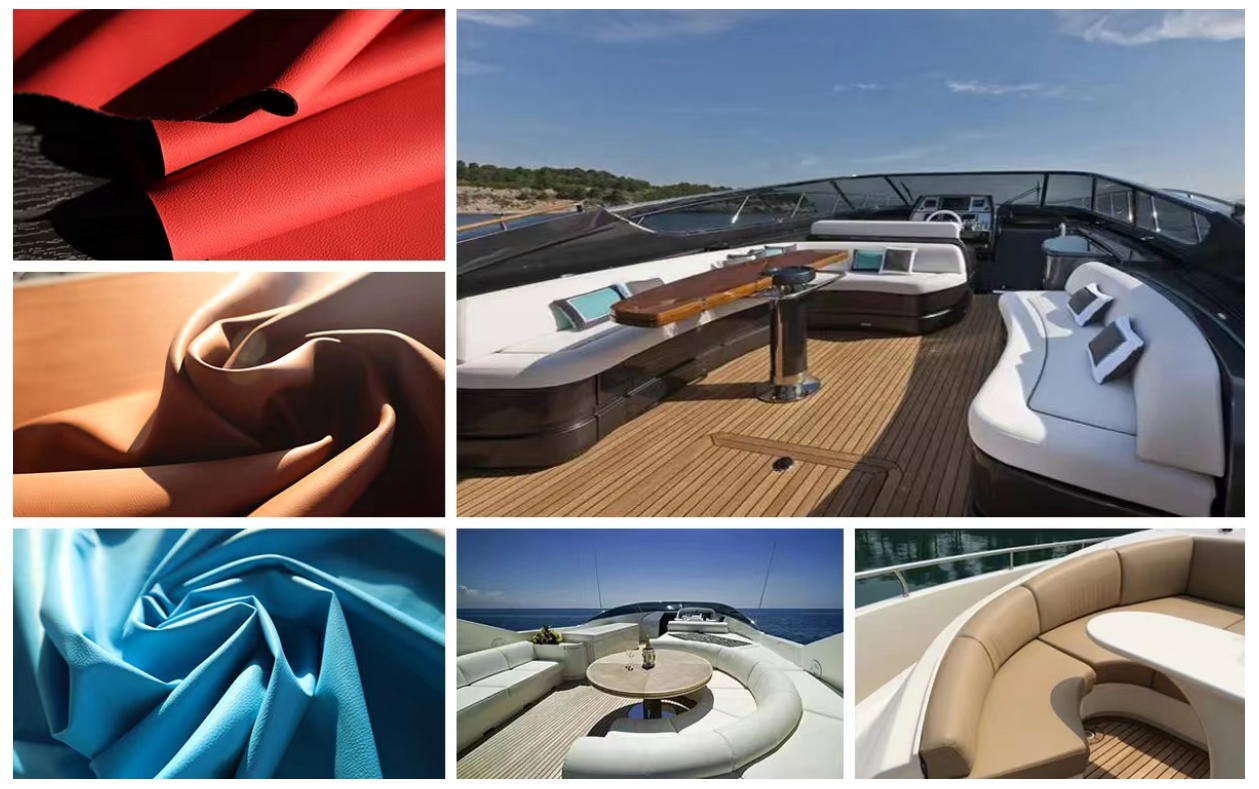

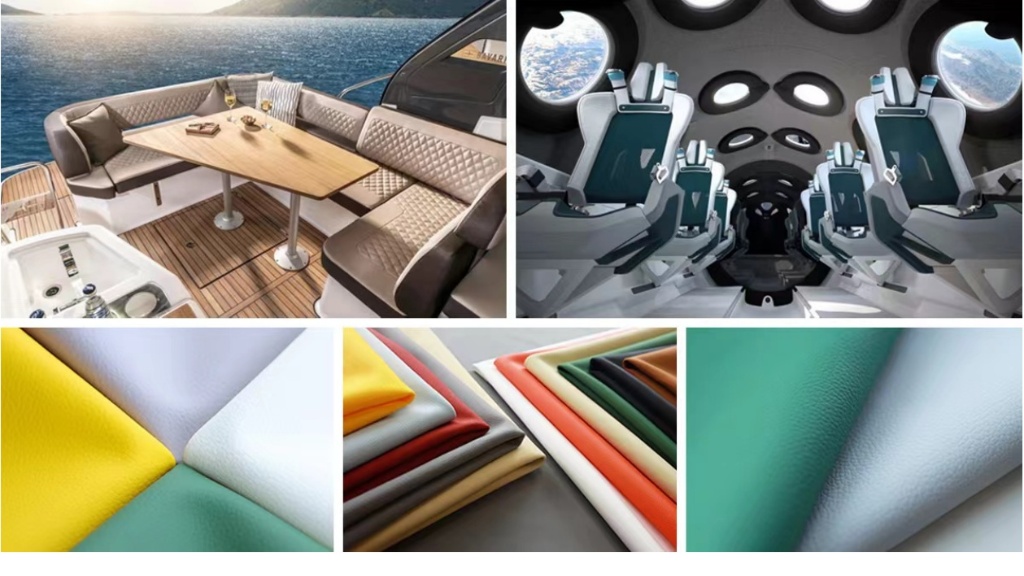

Silicone leather also has natural weather resistance, mainly manifested in its hydrolysis and light resistance; it will not be easily decomposed by ultraviolet rays and ozone, and there will be no obvious changes after soaking for 5 years under normal circumstances. It also performs well in resisting fading in the sun, and can still maintain its stability after 5 years of exposure. Therefore, it is also widely used in various outdoor places, such as table and chair cushions in public places, yacht and ship interiors, sofas, and various outdoor furniture and other common products.

Silicone leather can be said to provide the leather industry with a fashionable, novel, green and environmentally friendly high-performance fabric, which is an environmentally friendly leather that meets health standards.

Product Introduction

Low release, non-toxic

No harmful gas is released even in a high temperature and closed environment, protecting your health.

Easy to remove stains

Even boiling red oil hot pot will not leave any traces! Ordinary stains are as good as new with a wipe of paper towel!

Skin-friendly and comfortable

Medical grade materials, no allergy worries

Long-lasting and durable

Sweat-resistant, corrosion-resistant, scratch-resistant, can be used outdoors for more than 5 years

Silicone Leather Characteristics

Low VOC: The confined space cubic cabin test reaches the low release level of the car confined space

Environmental protection: Passed SGS environmental protection test REACH-SVHC 191 items of high concern substances test, non-toxic and harmless.

Inhibit mites: parasite mites cannot live and survive

Inhibit bacteria: built-in antibacterial function, reducing the risk of disease caused by germs

Non-allergenic: skin-friendly, non-allergic, comfortable and safe

Weather resistance: light will not damage the surface, even if there is sufficient light, there will be no aging for 5 years

Odorless: no obvious odor, no need to wait, buy and use

Sweat resistance: sweat will not damage the surface, use it with confidence

Easy to clean: easy to clean, ordinary stains can be cleaned with water, no or less detergent, further reducing pollution sources

Two Core Technologies

1.coating technology

2.production process

Research and development and breakthroughs in silicone rubber coatings

Revolution of coating raw materials

Petroleum products

VS

Silicate ore (sand and stone)

The coating materials used in traditional artificial leather, such as PVC, PU, TPU, acrylic resin, etc., are all carbon-based products. High-performance silicone coatings have broken away from the constraints of carbon-based materials, greatly reducing carbon emissions and complying with national environmental protection policies. Silicone synthetic leather, China leads! And 90% of the world's silicone monomer raw materials are produced in China.

The most scientific coating product

After more than 10 years, we have achieved great results in the research and development and synthesis of silicone rubber basic materials. At the same time, we have established good cooperation with universities and research institutions such as South China University of Technology, and have made full preparations for product iteration. Always ensure that product technology is more than 3 years ahead in the industry.

Really pollution-free green production process

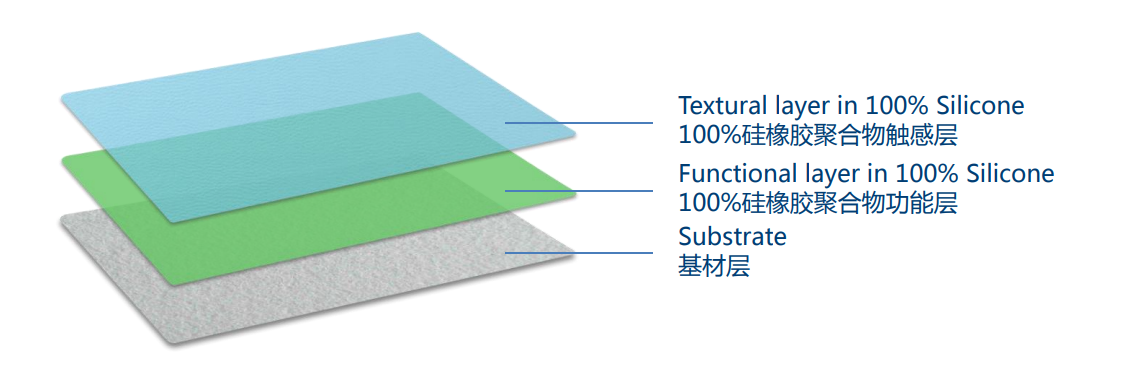

The production process of silicone leather mainly includes the following steps:

Substrate preparation: First, select a suitable substrate, which can be various types of substrates, such as environmentally friendly fibers.

Silicone coating: 100% silicone material is applied to the surface of the substrate. This step is usually completed by a dry process to ensure that the silicone covers the substrate evenly.

Heating and curing: The coated silicone is cured by heating, which may include heating in a thermal oil oven to ensure that the silicone is fully cured.

Multiple coatings: A three-coating method is used, including a top coating, a second intermediate layer, and a third primer. Heat curing is required after each coating.

Lamination and pressing: After the second intermediate layer is treated, the microfiber base cloth is laminated and pressed with the semi-dry three-layer silicone to ensure that the silicone is tightly bonded to the substrate.

Full curing: Finally, after the rubber roller machine presses, the silicone is fully cured to form silicone leather.

This process ensures the durability, waterproofness and environmental friendliness of silicone leather, while avoiding the use of harmful chemicals, meeting modern demands for environmentally friendly materials. The production process does not use water, has no water pollution, addition reaction, no toxic substance release, no air pollution, and the production workshop is clean and comfortable, ensuring the health and safety of production personnel.

Innovation of production supporting equipment

Automated energy-saving production line

The company team specially designed and developed the production line according to the production requirements of silicone leather. The production line has a high degree of automation, high efficiency and energy saving, and the power consumption is only 30% of traditional equipment with the same production capacity. Each production line only needs 3 people to operate normally.

Post time: Sep-14-2024